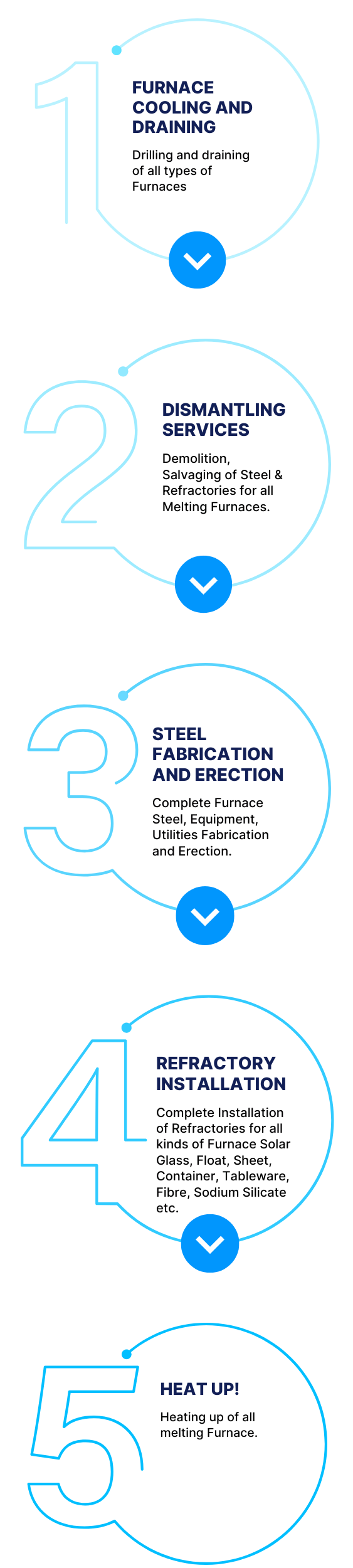

The key to Dukhiram’s extensive expertise in all fields of glass melting technology is due to our fundamental understanding of every detail involved in the entire process, making Dukhiram the specialist for each aspect of a glass plant. In addition to our expertise in every individual components of melting furnaces, Dukhiram has broadened its offerings to function as a comprehensive one-stop service provider from fabrication, modification erection of steel and equipment to installation of refractories, repair and maintenance support extending your furnace life cycle. Dukhiram stands by you all the way.

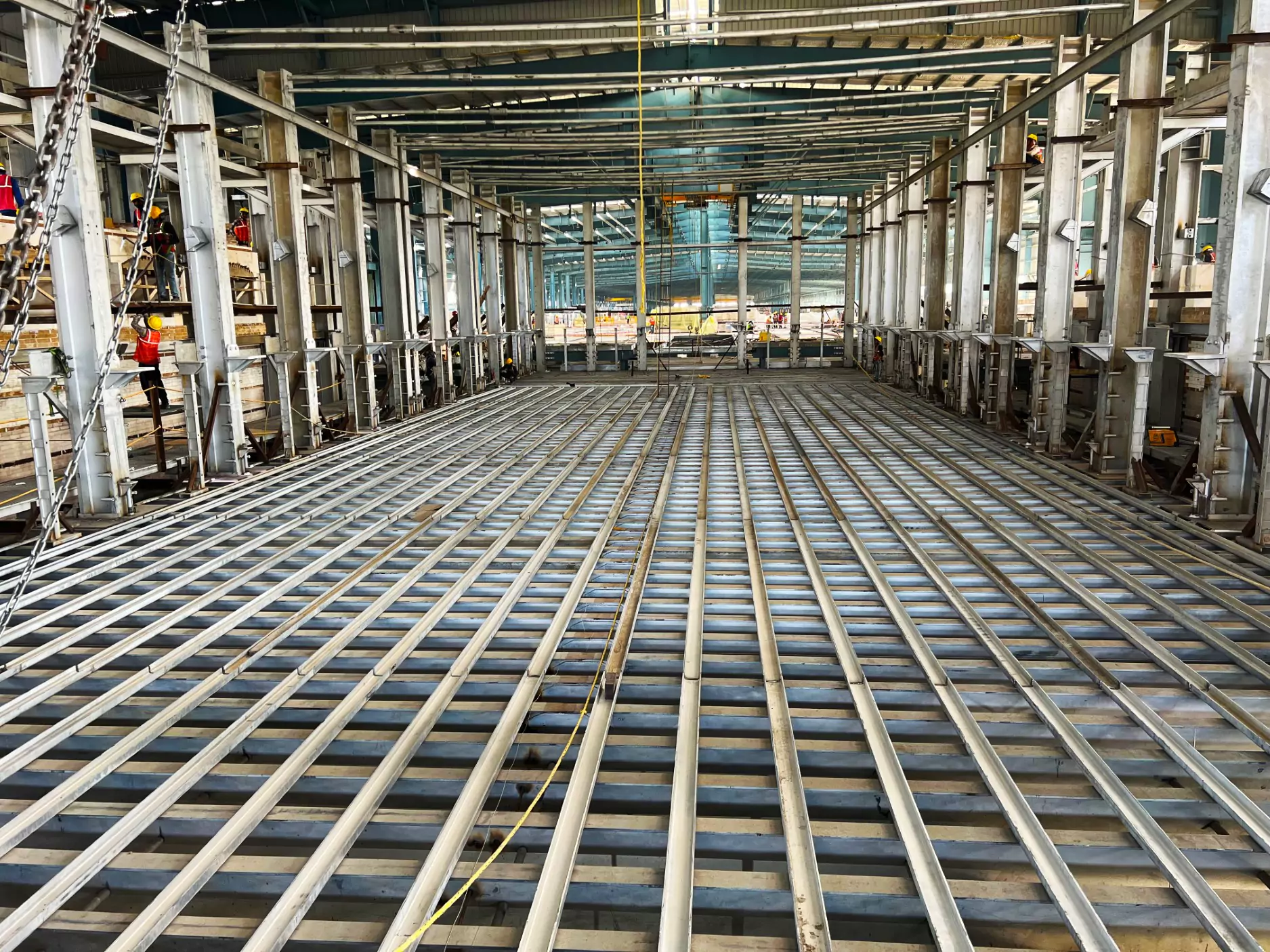

Fabrication & Erection of All Steels, Mechanical structures & Equipment

At dukhiram, our customers get a one stop solution for all steel and mechanical requirements. Complete Fabrication, Modification and Erection of Steel and Mechanical equipment for both Green field and Brown field Projects.

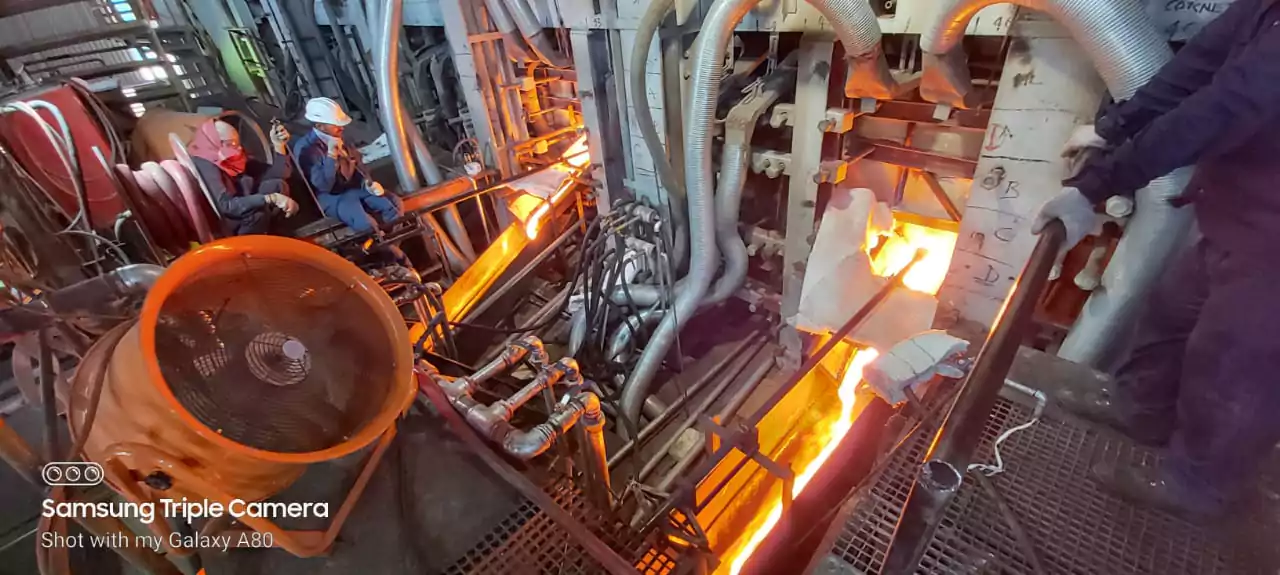

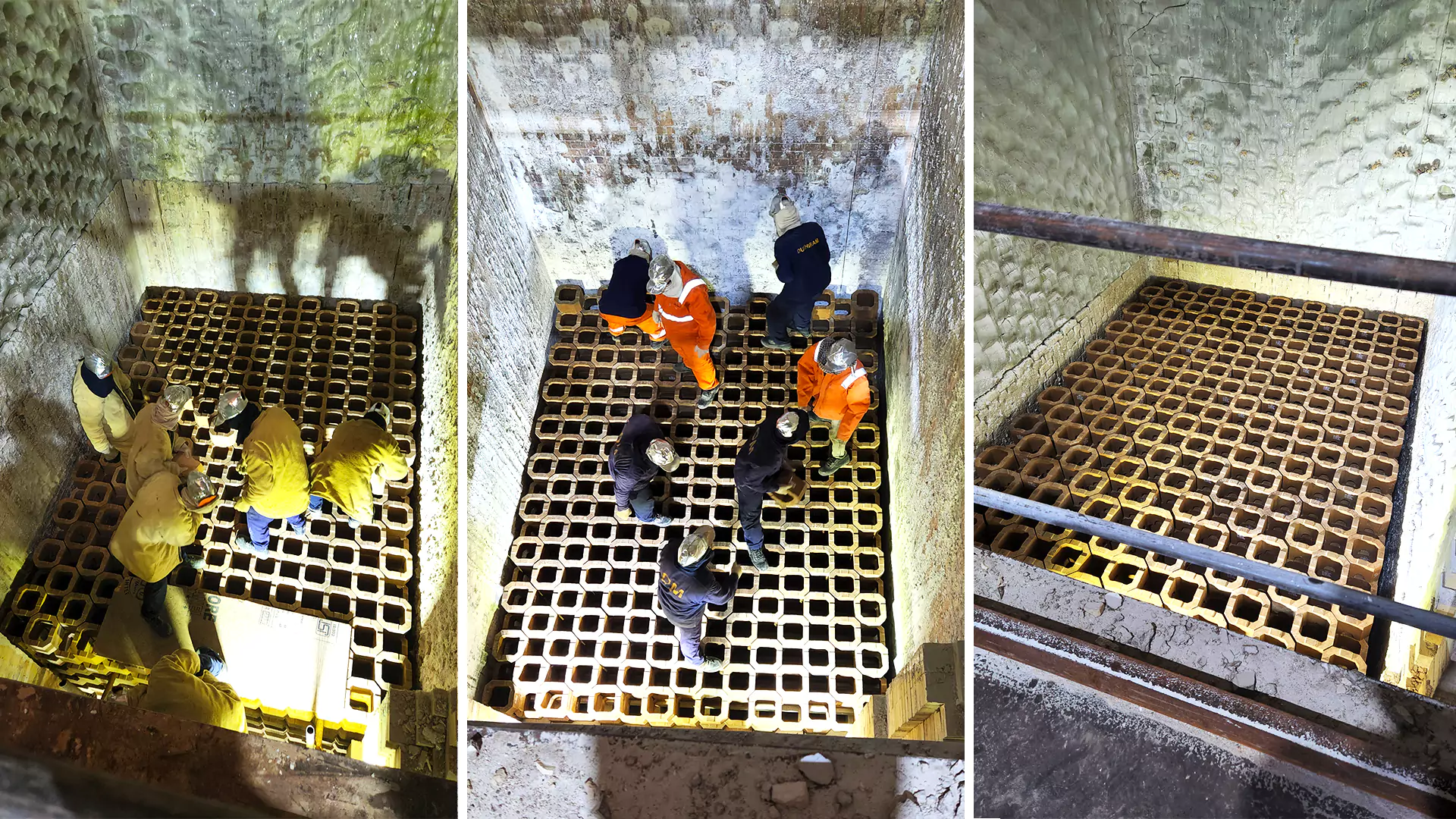

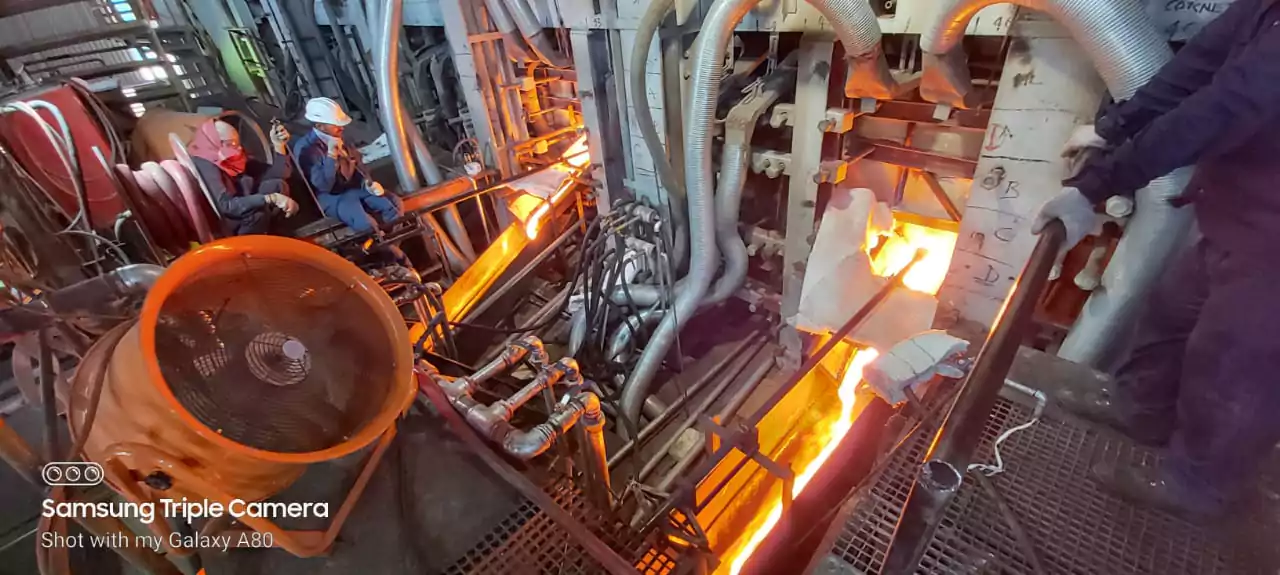

Furnace Construction – Refractory Lining

If you can dream it, we can build it. A one-stop shop for all refractory needs. Expertise in construction: Float, Sheet, End fired, Cross fired, Oxy – fuel, Container, Tableware, Fibre, Figured Sodium and Silicate furnaces.

Our Representative will get in touch with you soon.