Mechanical Services

Experience the Dukhiram Advantage

Choose Dukhiram an organisation that goes beyond industry standards. With a legacy spanning four decades and across two continents, Dukhiram provides excellence and a commitment to quality & precision. We are your trusted partner in achieving seamless and efficient construction, repair and maintenance of your furnaces. Experience the Dukhiram advantage and elevate your furnace construction to new heights.

Steel & Mechanical Fabrication

At Dukhiram Maurya Engineering & Refractory Works, we are more than fabricators and erectors; we are the architects of tomorrow’s industrial landscape. With a heritage steeped in tradition and a vision fuelled by innovation, we master the art of crafting and modifying structural steel, chimneys, and batch houses.

Our work stands as a symbol of prestige and excellence, where every structure represents a testament to our unwavering courage and commitment to pioneering progress.

Services Provided:

Fabrication & Erection:

- Structural Steel

- Chimney

- Batch house

- Equipment

Green Field Projects

Steel isn’t just a material to us; it’s the cornerstone of our craft. At Dukhiram Engineering & Refractory Works, we have mastered the craft of mechanical works. Our hefty work portfolio consists of Fabrication erection, modification of Robust structural steel, utilities, engineering comprehensive furnace equipments (Batch chargers, air, pressure and reversal dampers, ventilation systems, and so on), with an emphasis on sustainability and efficiency, we bring advancements to every detail. Our expertise further extends to optimising air, water pipelines, catwalks, platforms, and ladders.

We shape steel with precision and skill. From intricate components to monumental structures. Every project we undertake is a testament to quality, strength & resilience.

Services Provided:

Fabrication & Erection:

- Complete Structural Steel & Mechanical Works.

- Ventilation: Cooling ducts, blowers, fishtails & nozzles.

- Utilities: Air & Water Pipelines.

- Furnace Equipments: Batch Charger, Air Reversal Dampers,

Pressure control dampers etc. - Miscellaneous: Catwalk, Platform & Ladder.

Structural Steel Fabrication

Surface Cleaning

Burs or other unwanted shapes are removed from the surface.

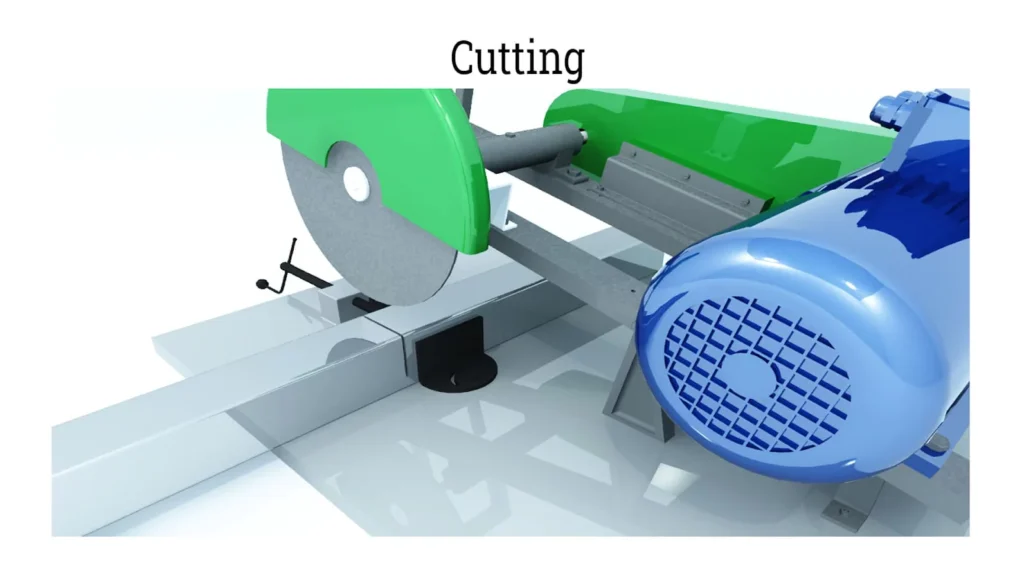

Cutting

Following to the surface cleaning, sections are properly sized.

Straigthening, Bending and Rolling

Fitting and Reaming

Rivets, bolts or other attachments are fitted.

Fastening

Riveting, bolting and welding are applied.

Surface Treatise

Due to the requirements. alteration of surface can be necessary.

Fastening

Riveting, bolting and welding are applied.

Quality Control

Quality assurance is maintained for proper mathcing of end product and design.

Steel fabrication encompasses a series of intricate processes aimed at transforming raw steel into various structures, ranging from frames to platforms and ladders. These processes involve meticulous attention to detail and skilled craftsmanship to ensure the final product meets stringent quality standards. Let’s delve into the systematic steps involved in steel fabrication:

Surface Cleaning:

The initial step in steel fabrication is meticulously cleaning the surface of the steel to remove any mill scale and rust. Various methods, such as hand preparation using wire brushes and emery paper, are employed to achieve a clean and smooth surface, essential for subsequent fabrication processes.

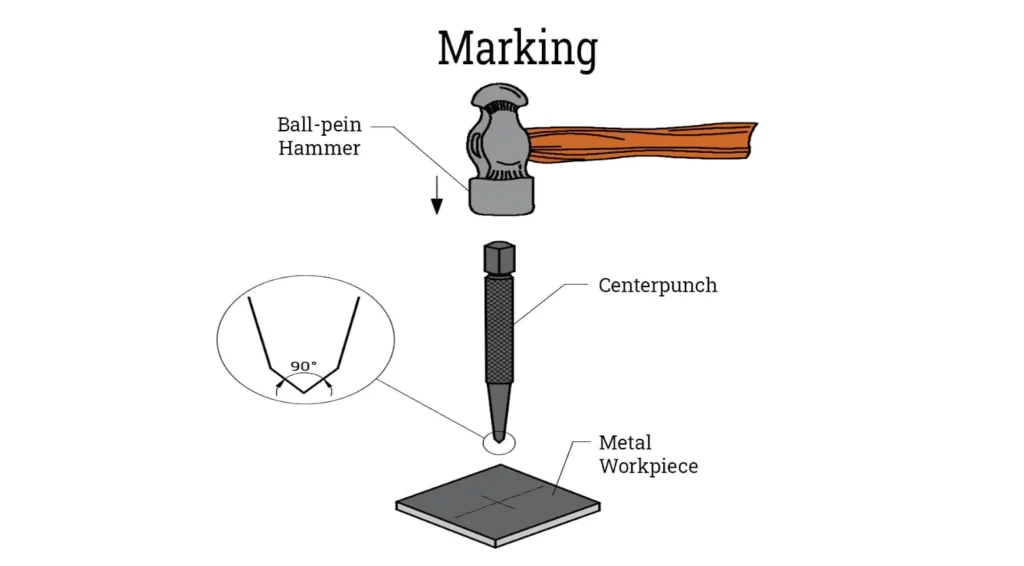

Marking:

Marking is the process of laying off the measurements from the design and into the workpiece. This is sometimes included in the preparation process. Edges, fold lines, and hole centers are scribed on the surface of the workpiece. These scribes or marks must remain visible during the actual fabrication. Common marking tools are metal scribers, pencils, chalks, dividers, and punches. Aside from the measuring devices, marking is aided by tools such as rulers, center squares, and Tsquares.

Cutting and Machining:

Following surface cleaning, the steel undergoes cutting and machining processes to shape it according to the desired specifications. This includes shaping, drilling, turning, and grinding. Different cutting methods like shearing, flame cutting and cold sawing are employed based on the thickness and type of steel.

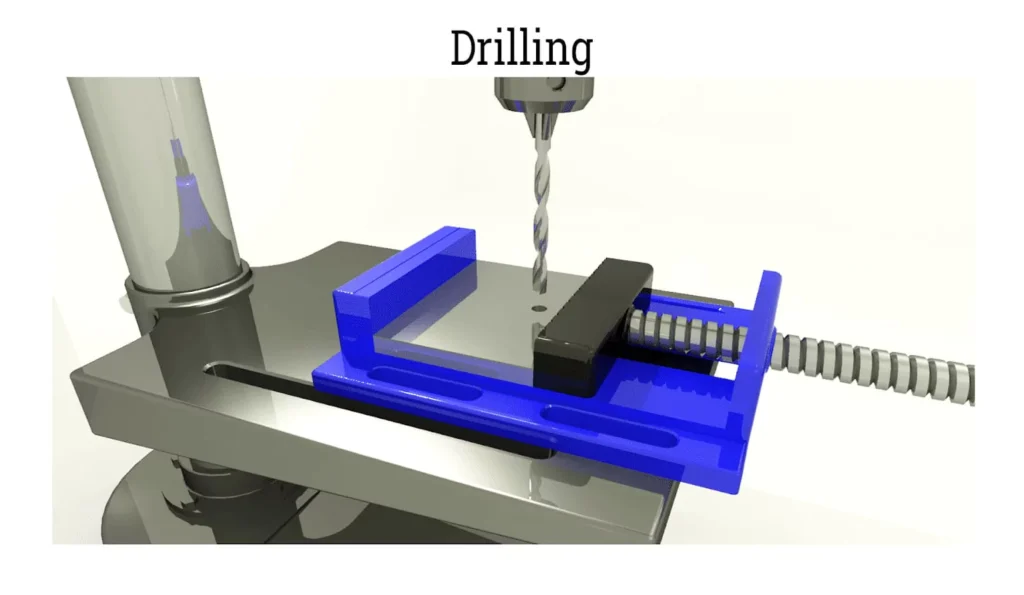

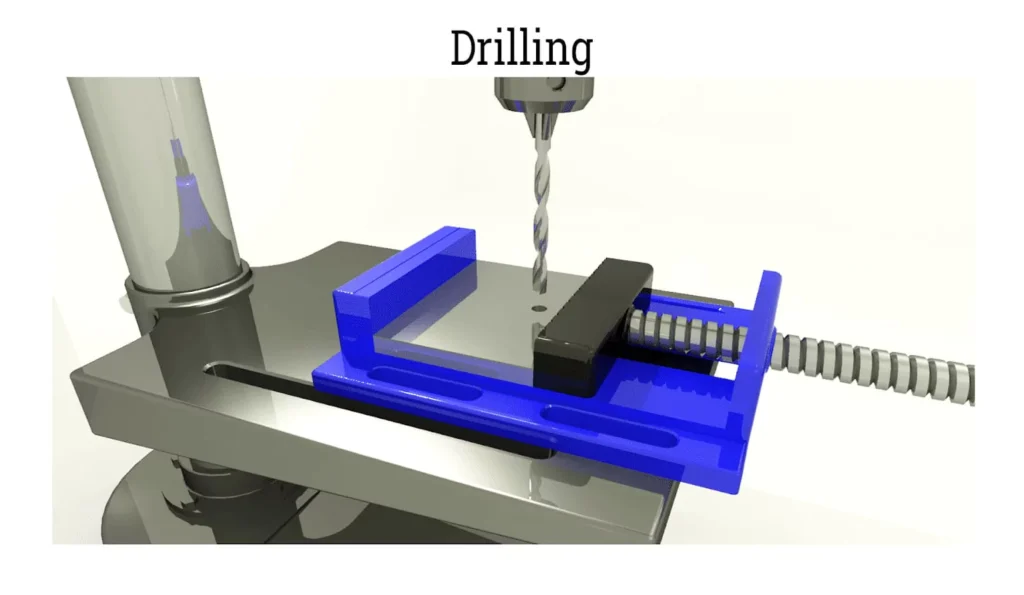

Punching and Drilling:

Punching and drilling involve creating holes in the steel components using specialised equipment. These holes are crucial for joining components together and accommodating fasteners such as bolts and screws.

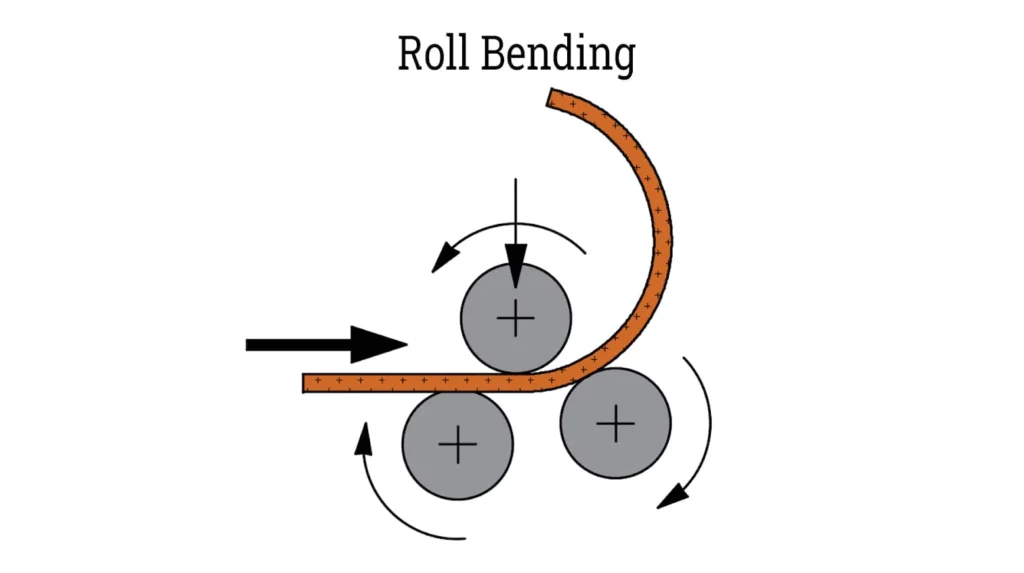

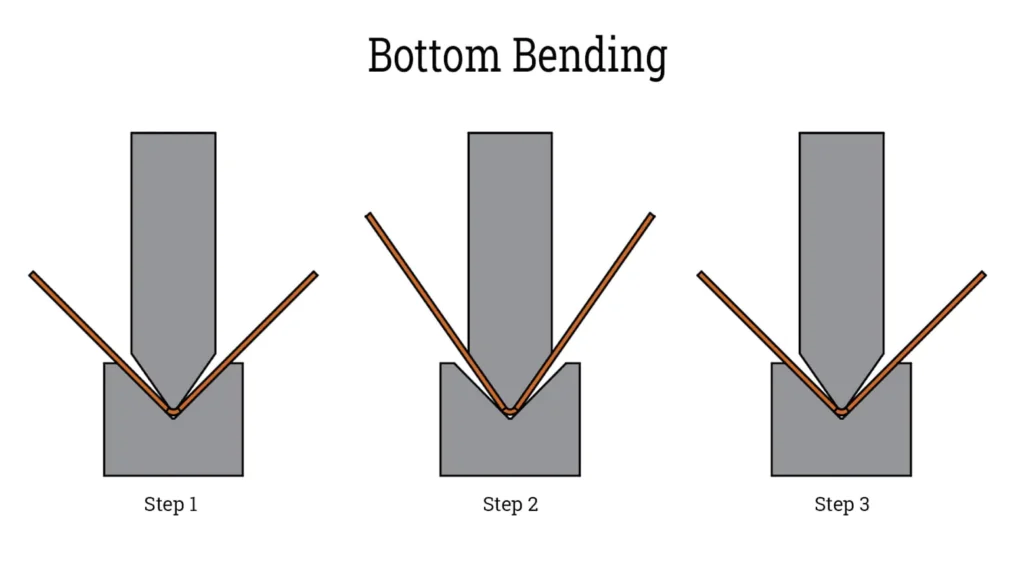

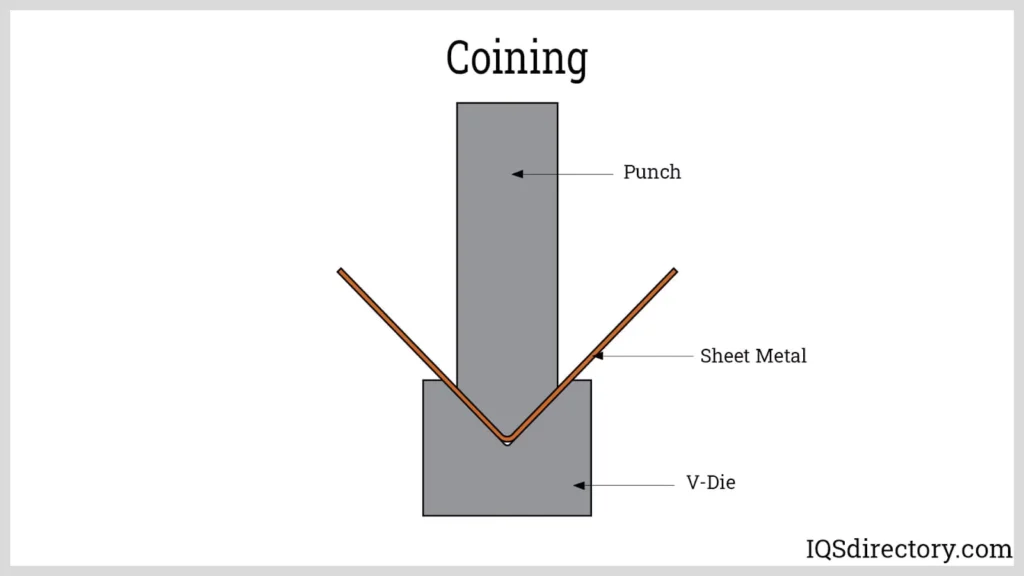

Bending, and Rolling:

After cutting and drilling, the steel may undergo straightening, bending, and rolling processes to achieve the desired shapes and dimensions. Roller bending and folding are commonly used methods to bend and shape the steel according to specific design requirements.

Fitting:

Fitting involves aligning and temporarily joining steel components through tack welding to ensure proper assembly before final welding. This step is crucial for achieving precise alignment and structural integrity.

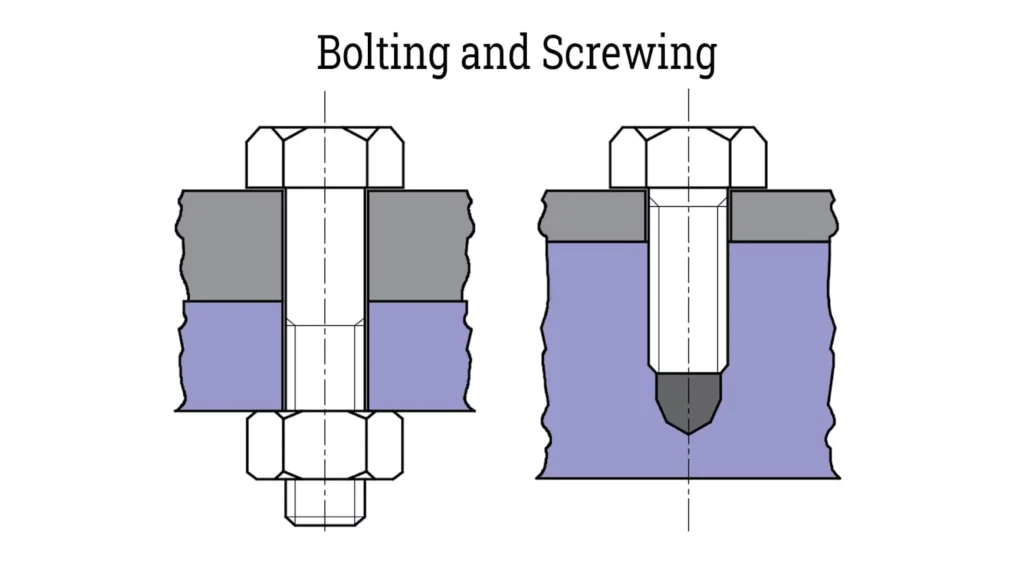

Methods for the Fastening process:

Essentially, there are three different types we can join the parts of the structure.

- Bolting: In this process, bolts and nuts create joints between structural elements and fasten them.

- Riveting: This method uses permanent mechanical fasteners, also known as rivets. Which helps fasten structural elements together.

- Welding: This method uses heat and pressure to fasten. The fastened parts form a joint after cooling.

Welding:

Precision welding plays a vital role in steel fabrication, as it joins individual steel pieces together to form cohesive structures. Skilled welders employ heat to fuse the metal pieces, creating strong and durable joints that withstand rigorous use.

Final Step:

Surface Treatment:

The final step of the manufacturing process of steel fabrication is Surface treatment. In this step, blasting, painting, or galvanizing treats the surface of the finished product to achieve certain benefits.

Primary methods for Surface Treatment:

- Blasting and painting: The professionals use the blasting technique on the finished product to smoothen the rough surfaces, remove surface contaminants or shape a surface. A two-layered process of painting follows the blasting.

- Preliminary step is the application of Red oxide or Zinc oxide. It forms a prime coat on the steel surface.

- Final step is forming an outer layer for beauty and protection. The application of oil, epoxy or other types of paint forms this outer layer.

Main Steps of Structural Steel Fabrication Process

Design Preparation

Drawings and specifications for the project are created and agreed. Draftsman can start creating exact Bill of Material (BOM) and Bill of operations (BOO).

Material Acquisition

Purchases will take it over to acquire the required materials for the project. Involves ordering the steel.

Steel Cutting and Drilling

Time to bend and weld the steel. Various bending processes are performed to create the desired shape.

Bending and welding

Time to bend and weld the steel. Various bending processes are performed to create the desired shape.

Quality Check

Visual inspections, dimensional inspections, and mechanical tests. Non-destructive testing (NBT) is also performed.

Finishing

Steel is then sandblasted and painted. The finishing process is performed before installation.

Delivery, Assembly, and Installation

The assembly process usually involves bolting, riveting, or welding the steel parts together.

Complete

Glass To Glass Solution