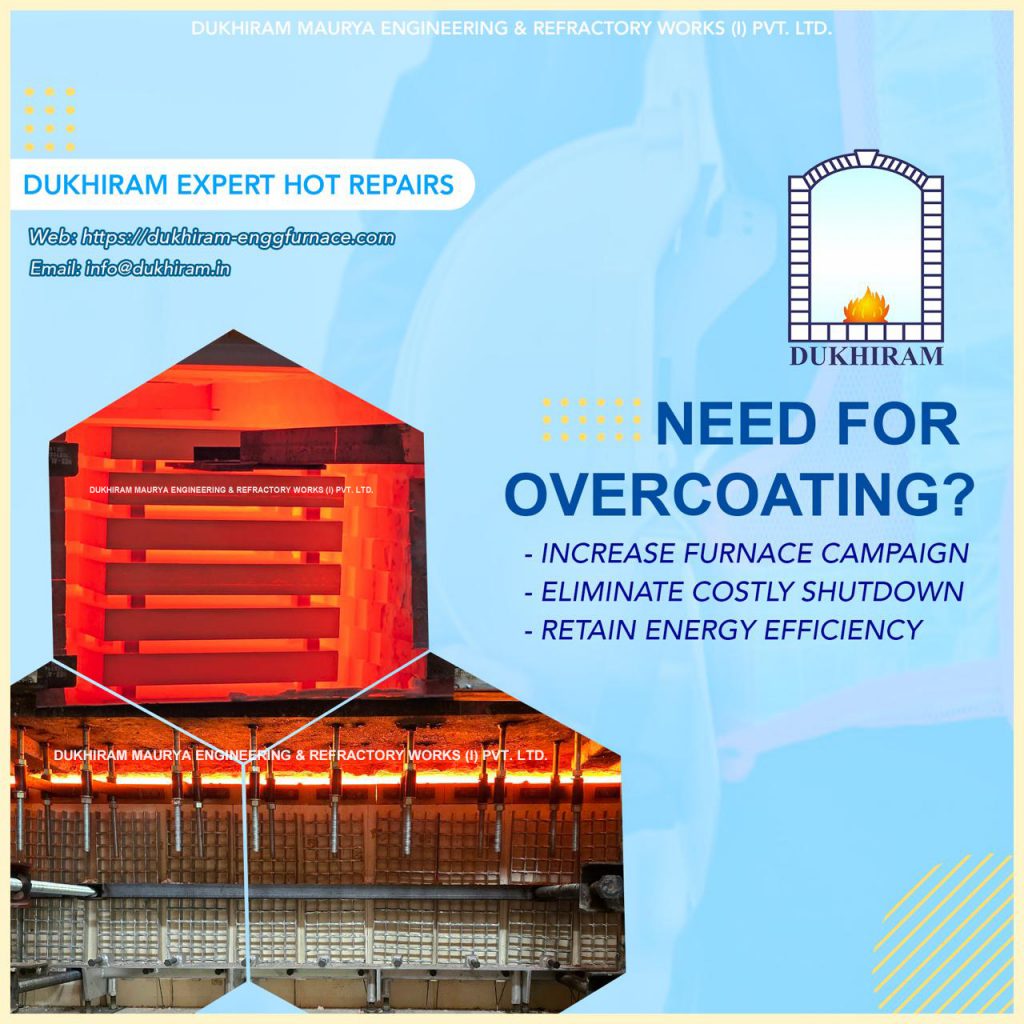

Dukhiram Maurya Engineering & Refractory Works (I) Pvt. Ltd. proudly announces the successful completion of the Hot Overcoating of Float Furnace, a significant milestone accomplished 2 days ahead of schedule. This achievement underscores our relentless dedication to project efficiency, safety, and client satisfaction, reinforcing our leadership position within the Hot Repair Industry for Glass Melting Furnaces.

Project Overview:

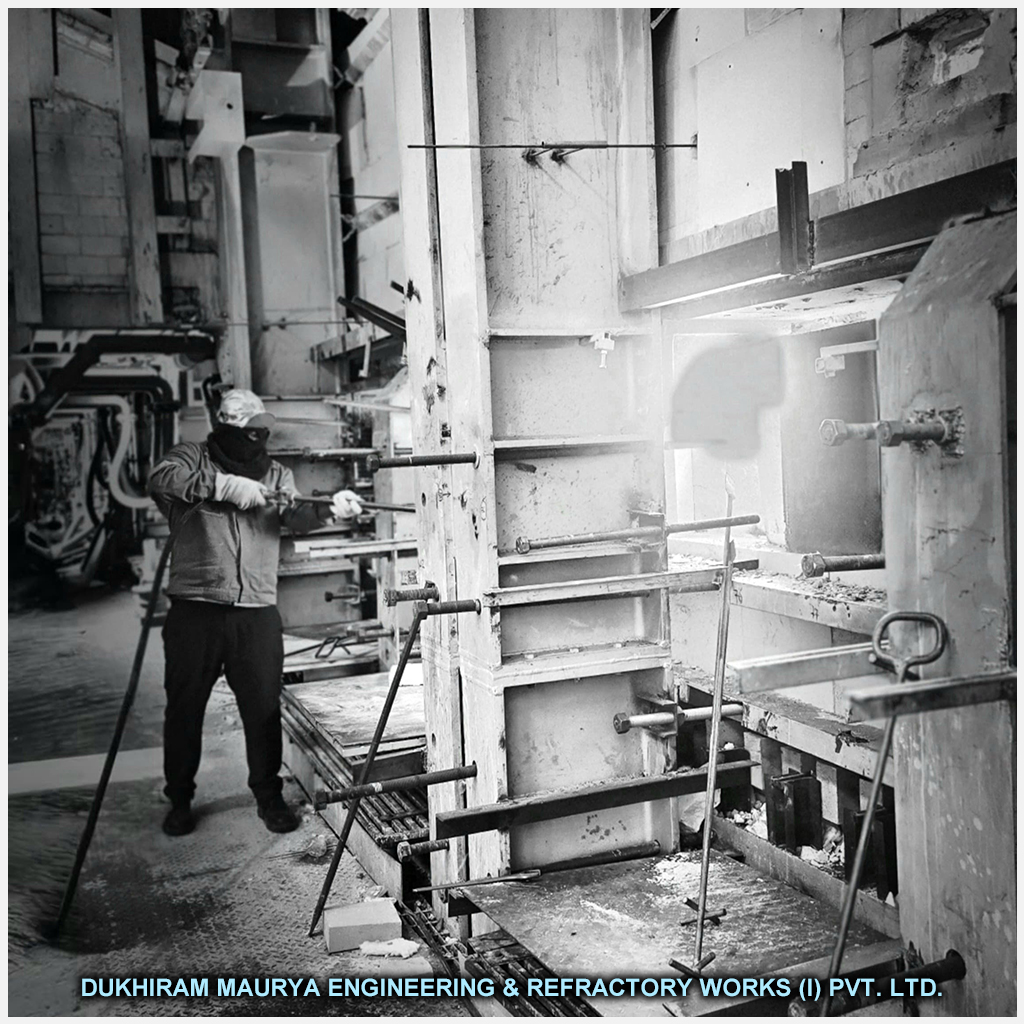

We recently completed the Hot Overcoating project of float furnace in Gujarat, India, of Melting Tank, Refiner, and Waist Exit sections. The complexity of the operation demanded meticulous planning, advanced equipment, comprehensive Personal Protective Equipment (PPE), and a highly skilled and experienced team. Our expert team successfully executed the project, delivering exceptional workmanship that met and exceeded our client’s stringent quality standards and expectations. Additionally, our efforts ensured that furnace operations continued uninterrupted throughout the project duration.

The Journey to Success

Key factors contributing to our successful project delivery include:

- Ahead-of-Schedule Completion:

Completing the project 2 days earlier than planned significantly reduced downtime, ensuring continued productivity for our client and reinforcing their early production goals.

- Use of Latest Tools, Equipment & Safety:

Dukhiram consistently invests in the latest technological advancements, tools, tackles, and sophisticated equipment. These assets significantly increased our team’s work efficiency, accuracy, and productivity, allowing precise execution and enhanced coordination across project phases.

- Unmatched Quality & Craftsmanship:

Our unwavering commitment to superior workmanship ensured the hot overcoating was performed flawlessly. This not only enhanced the furnace’s longevity but also optimized its performance, meeting the precise specifications and expectations set forth by our client.